2025 Guide: How to Choose the Right BNC Connectors for Your Project

In the ever-evolving landscape of electronic connections, selecting the right components can significantly impact the performance of your project. BNC connectors, renowned for their reliable and robust design, are essential in various applications ranging from telecommunications to broadcast and video equipment. As industry expert Dr. Emily Carter, a leading voice in connector technology, emphasizes, “Choosing the correct BNC connectors not only ensures optimal signal integrity but also enhances the overall efficiency of electronic systems.”

With a multitude of options available, it’s crucial to understand the specific requirements of your project. Factors such as frequency range, impedance, and environmental conditions will dictate the right type of BNC connectors to use. Dr. Carter further notes, “A thorough analysis of your project's needs can mitigate potential issues down the line, facilitating a seamless integration into your overall setup.” By focusing on these elements and leveraging expert insights, engineers and hobbyists alike can make informed decisions that bolster their project's success.

As we delve into this guide, we will explore the key considerations and best practices for selecting BNC connectors, ensuring that whether you are working on a simple prototype or a complex system, you have the knowledge to choose the right connectors confidently.

Understanding the Basics of BNC Connectors and Their Applications

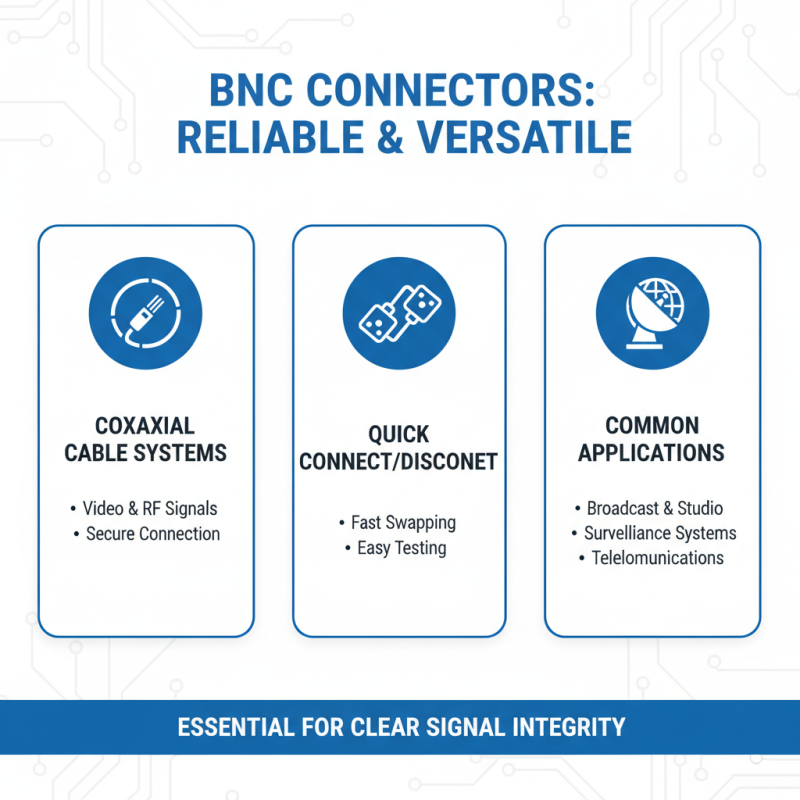

BNC connectors, or Bayonet Neill-Concelman connectors, are a popular choice for various applications due to their reliable performance and versatility. These connectors are primarily used in coaxial cable systems for video and RF signal transmission. Their design allows for quick connection and disconnection, making them ideal for situations where cables must be frequently changed or tested. BNC connectors are commonly found in broadcast, surveillance, and telecommunications settings, where clear signal integrity is paramount.

When selecting the right BNC connectors for your project, it’s crucial to consider factors such as cable type, frequency requirements, and environmental conditions. For instance, if your application involves high-frequency signals, ensure you choose connectors rated for those frequencies to prevent signal degradation. Additionally, consider the environment where the connectors will be used; ruggedized connectors might be necessary for outdoor applications, while standard models might suffice for indoor use.

Tips: Always check the specifications of both your cables and connectors to ensure compatibility. It’s also advisable to invest in quality BNC connectors to guarantee optimal signal transmission. Lastly, don’t overlook the importance of proper installation; incorrect assembly can lead to connection issues and signal loss, undermining the overall effectiveness of your project.

Key Factors to Consider When Selecting BNC Connectors

When selecting BNC connectors for your project, several key factors must be considered to ensure optimal performance and reliability. One of the primary considerations is the frequency range of the signals being transmitted.

According to a report by MarketsandMarkets, the global BNC connector market is expected to grow at a CAGR of 5.2% from 2020 to 2025, driven largely by the increasing demand for high-frequency applications in telecommunications. It is crucial to choose connectors that can handle the required frequency without significant signal degradation, which is especially important in applications like video transmission and RF communication.

Another critical factor to evaluate is the connector's construction and material quality. Connectors constructed from high-quality materials such as copper alloy and gold plating provide better conductivity and corrosion resistance, extending the life of the connection. A study published by the International Journal of Electronics states that connectors with superior surface finishes can reduce insertion loss by as much as 0.5 dB at high frequencies.

Additionally, consider the environmental conditions the connectors will be exposed to, including temperature and humidity, as these can significantly impact performance. Proper understanding of these parameters can lead to more informed decisions, ultimately enhancing system reliability and functionality.

Different Types of BNC Connectors and Their Specifications

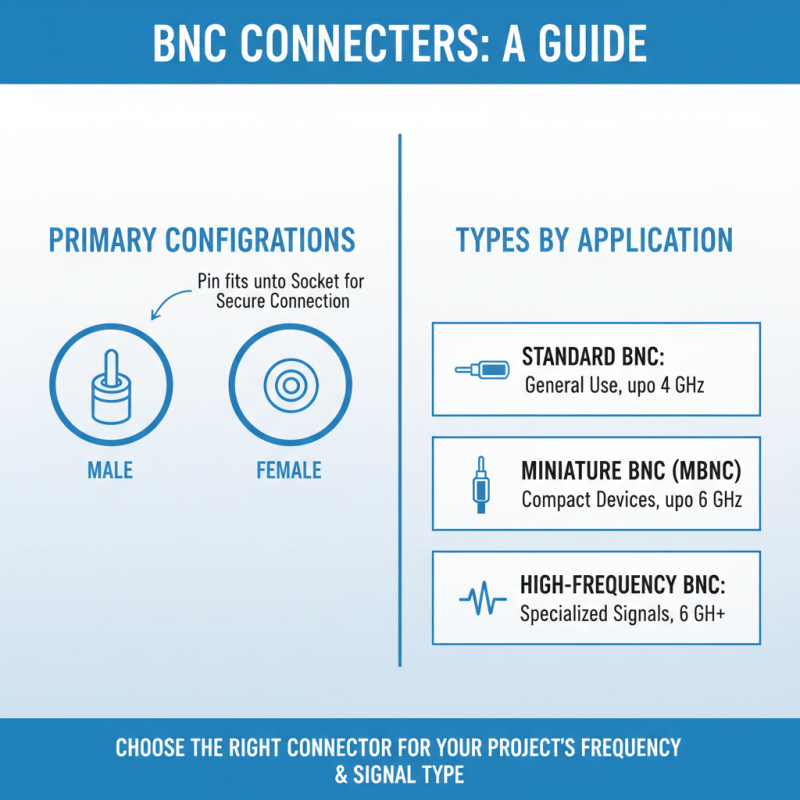

When it comes to BNC connectors, understanding the different types and their specifications is crucial for selecting the right one for your project. BNC connectors primarily come in two configurations: male and female. The male connector features a pin that fits into the female connector's socket, establishing a secure connection. Additionally, they can be categorized into different types based on their application, such as standard BNC, miniature BNC, and high-frequency variants, each designed to handle specific frequency ranges and signal types effectively.

Tips for choosing the correct BNC connector include paying attention to the frequency rating and impedance. Standard BNC connectors typically have an impedance of 75 ohms, ideal for video applications, while 50-ohm connectors are better suited for radio frequency communications. Furthermore, consider the environment where the connectors will be used; options like weatherproof or gold-plated connectors can enhance durability and signal quality.

Another important factor is the cable type. Ensure that the BNC connector you choose matches the cable specifications, as mismatched connectors can lead to poor performance and signal loss. It’s always a good practice to verify the connector's compatibility with your equipment to ensure optimal results in your projects.

Best Practices for Installing BNC Connectors in Your Project

When it comes to installing BNC connectors, ensuring proper installation techniques is crucial for achieving optimal performance. According to a recent industry report by the International Society of Automation, approximately 30% of connection failures stem from improper installation procedures. To mitigate this risk, it is essential to follow best practices such as ensuring that the cable is stripped to the correct length and the inner conductor is fully seated within the connector. This prevents signal loss and maintains the integrity of the transmission.

Additionally, it is vital to utilize appropriate tools and methods during the installation. Using a high-quality crimping tool can significantly enhance the mechanical reliability of the connection, as highlighted in a study published by the Cable and Connector Association, which showed that connectors installed with proper tools exhibit a 40% lower failure rate compared to those installed with insufficient techniques. Properly testing all connections with a cable tester post-installation ensures that the BNC connectors function as intended, providing peace of mind and reliability in critical applications.

Moreover, environmental factors should not be overlooked. The effects of temperature variations and humidity can impact connection quality, thus selecting connectors rated for specific environments is recommended. According to the Electrical Contractors Association, connectors designed for outdoor use can sustain harsher conditions, reducing downtime and maintenance needs in the long run. Therefore, focusing on diligent installation practices and environmental considerations can significantly enhance the performance and longevity of BNC connectors in any project.

Common Mistakes to Avoid When Choosing BNC Connectors

When selecting BNC connectors for your project, it's easy to overlook critical factors that can lead to performance issues. One common mistake is ignoring the specifications of your equipment, such as impedance and frequency range. BNC connectors typically come in 50-ohm and 75-ohm variants, and choosing the wrong one can result in signal loss and reflections that compromise data integrity. Always ensure that the connector's impedance matches your application's requirements to maintain optimal performance.

Another frequent error is failing to consider the environment where the connectors will be deployed. Connectors designed for harsh conditions, such as high humidity or extreme temperatures, differ significantly from those used in controlled indoor settings. Ignoring environmental factors can lead to premature connector failure, resulting in costly repairs and downtime. It's essential to assess the operating conditions thoroughly and select connectors that are specifically rated for those challenges, ensuring reliability and longevity in your project.

Related Posts

-

Ultimate Guide to Choosing the Best BNC Cables for Your Home Network

-

How to Choose the Right Patch Panels for Your Network Setup

-

Why You Should Choose Fiber Optic Patch Cable for Reliable High Speed Internet Connection

-

What Are Cable Connectors? Types, Uses, and Installation Guide Explained

-

Ultimate Guide to Choosing the Right Patch Cable for Your Networking Needs

-

2025 Top 5 Telephone Cables: Enhance Your Connectivity Experience Today