How to Choose the Right Cable Assemblies for Your Projects?

When working on electronic projects, making the right choice in cable assemblies is crucial. According to Dr. Emily Carter, a leading expert in the cable assemblies industry, “Choosing the right cable assembly can make or break your project.” This statement emphasizes the importance of selecting high-quality components that match your specific needs.

Many factors influence your decision. Consider the project requirements, the environment, and the cable's electrical characteristics. For example, custom cable assemblies can provide flexibility and performance. However, they often entail longer lead times and increased costs. Balancing the trade-offs can be challenging.

Every project is unique, demanding careful consideration. It's easy to overlook critical details when under tight deadlines. Rushed decisions may lead to problems down the line. Reflecting on your choices can prevent wasted resources. In cable assemblies, the right decision ensures reliability and effectiveness in your projects.

Understanding Cable Assemblies and Their Components

Cable assemblies play a critical role in electrical systems. They consist of multiple components, ensuring reliable signal and power transfer. Understanding these components is key to making informed choices for various applications. According to a recent industry report, the global cable assembly market is projected to grow by 5.1% annually through 2027. This growth highlights the increasing importance of quality cable assemblies.

When selecting cable assemblies, consider the wire type, insulation material, and connectors. Different projects require specific characteristics. For example, automotive applications often need durable, heat-resistant materials. In contrast, medical devices may prioritize flexibility and biocompatibility. However, not every assembly performs optimally in every environment. Testing in real conditions is often necessary.

Moreover, understanding the technical specifications can be overwhelming. Many professionals overlook the impact of connector types. Misalignment here can lead to failures. Research indicates that 30% of cable assembly faults stem from improper connector use. It's essential to review compatibility before making a decision. A thoughtful selection can significantly enhance performance and reliability in any project.

Comparison of Cable Assembly Types

Identifying the Specific Requirements for Your Project

When selecting cable assemblies for your projects, understanding your specific requirements is crucial. Different applications demand different specifications. For instance, a report by the Electrical Contractors Association highlights that 67% of project failures stem from inadequate cable selection. Mistakes can lead to performance issues and delays.

Consider the environment where the cable assemblies will be used. Will they be exposed to moisture, extreme temperatures, or chemicals? The National Electrical Manufacturers Association suggests that cables in harsh environments should have higher ratings for durability. Another aspect to evaluate is the signaling type—analog, digital, or power transmission. Each has unique requirements that could affect performance.

Feel free to reflect on your experiences. Have you faced challenges with cable assembly decisions in your past projects? This is common. According to a survey from Electronics Weekly, 45% of engineers wish they had better guidance on cable specifications. Understanding the nuances can help avoid costly mistakes. Identify your needs, and you'll be much closer to a successful selection.

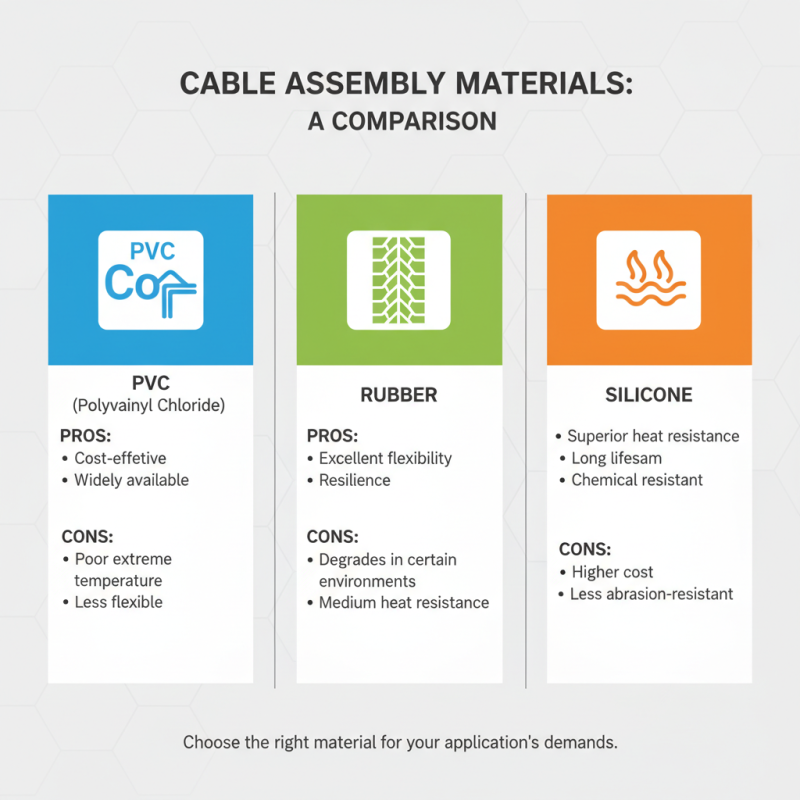

Evaluating Material Options for Durability and Performance

When selecting cable assemblies, material choice greatly influences durability and performance. The most common materials include PVC, rubber, and silicone. PVC is widely used due to its cost-effectiveness, but it may not endure extreme temperatures well. Rubber offers excellent flexibility and resilience, yet can degrade under certain environmental conditions. Silicone, although pricier, provides superior heat resistance and longevity.

Consider the specific needs of your project. Do you require flexibility or rigidity? Assess the environment the cables will face. If they encounter moisture or heat, silicone may be your best bet. However, think about the trade-offs. Is the added cost justifiable? Will PVC suffice for less demanding applications?

Sometimes, it’s easy to overlook the long-term impact of material choice. A cheaper option today might lead to failures tomorrow. Reflect on your project’s goals. Prioritize performance over initial costs. The right material can enhance cable longevity and reliability, ensuring your project’s success.

Choosing Connectors and Termination Methods

Choosing the right connectors and termination methods is crucial for your cable assemblies.

Connectors come in various types, such as circular,

rectangular, and modular.

Each type serves specific applications. When selecting, consider the environment. Will they be exposed to moisture or dust?

Environmental factors impact performance.

Termination methods also play a key role.

Soldering is common, but it requires skill. Crimping is quicker, yet can lead to weak connections if not done right.

Choosing the wrong method may result in failures. Think about your project’s needs before making decisions.

Tips: Always test your connections. A small test can prevent costly errors later.

Keep your workspace organized to avoid mistakes. Remember, every detail matters.

This will help in maintaining the integrity of your assembly. Be ready to reassess your choices if problems arise.

Adaptability is essential for success.

Ensuring Compatibility and Compliance with Industry Standards

Choosing the right cable assemblies begins with understanding compatibility and compliance. A recent report indicates that non-compliance issues can lead to costly project delays. Ensuring your cable assemblies meet industry standards is essential. Many manufacturers follow guidelines established by organizations like IPC and ISO.

You need to know specific requirements. For example, the IPC/WHMA-A-620 standard outlines criteria for cable and harness assembly. It covers everything from soldering techniques to insulation specifications. When you select assemblies that adhere to these guidelines, you minimize risks. However, some designers overlook these standards, leading to assembly failures.

Consider also the importance of testing. A National Instruments study found that approximately 30% of cable failures result from inadequate testing procedures. Regular inspections and compliance checks can save time and resources later. Without proper procedures, your project may face unexpected setbacks. Prioritize compliance to ensure reliability and efficiency in your designs.

Related Posts

-

The Ultimate Guide to Understanding Wire Cable Types for Your Projects

-

Ultimate Guide to Choosing the Best BNC Cables for Your Home Network

-

Why You Should Choose Fiber Optic Patch Cable for Reliable High Speed Internet Connection

-

2025 Guide: How to Choose the Right BNC Connectors for Your Project

-

How to Choose the Right Wire Cable for Your Electrical Project

-

Ultimate Guide to Choosing the Right Patch Cable for Your Networking Needs