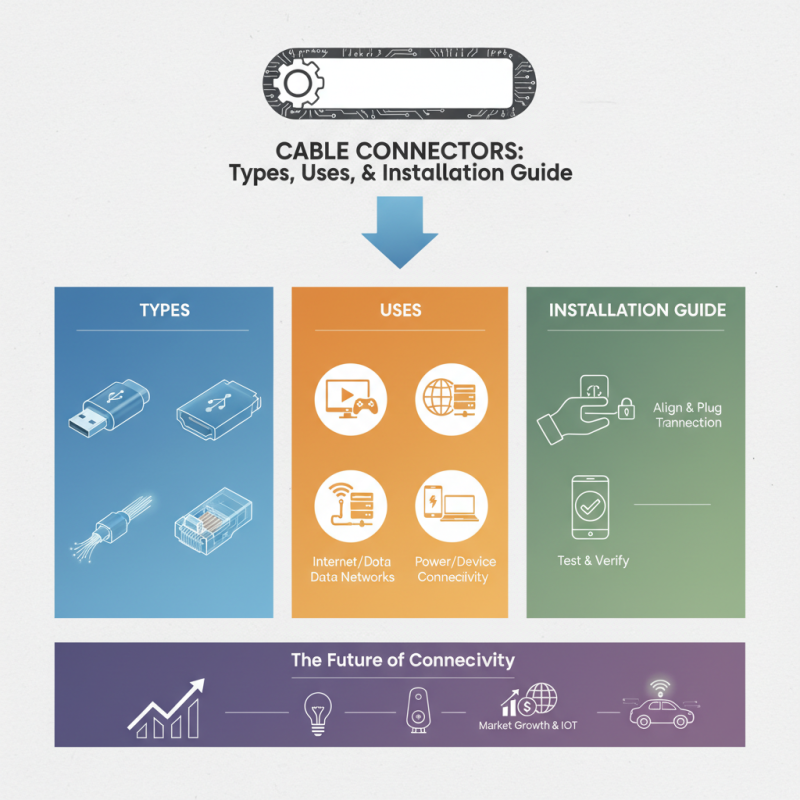

What Are Cable Connectors? Types, Uses, and Installation Guide Explained

Cable connectors are essential components in modern electrical and communication systems, playing a critical role in ensuring effective connectivity between devices and facilitating data transmission. According to industry reports, the global cable assembly market, which heavily relies on various types of cable connectors, is projected to reach USD 200 billion by 2026, with a compound annual growth rate (CAGR) of 6.5% from 2021 to 2026. This growth is driven by the increasing demand for reliable and efficient connectivity solutions across sectors such as telecommunications, automotive, and consumer electronics.

The diverse types of cable connectors—including USB, HDMI, RJ45, and fiber optic connectors—serve specific purposes and application environments. From transmitting high-definition video signals to establishing robust internet connections, each type of connector has its unique specifications and installation guidelines. With the rise of smart technology and the Internet of Things (IoT), understanding cable connectors and their applications is more critical than ever. Educating professionals and consumers alike about the correct types, uses, and installation methods can significantly enhance the performance and longevity of electronic devices, ultimately contributing to the overall efficiency of modern connectivity solutions.

Overview of Cable Connectors: Definition and Importance

Cable connectors are essential components in electronic and electrical systems, facilitating the connection and disconnection of various devices. They serve as the critical link between cables and devices such as computers, audio equipment, and even large industrial machinery. According to a recent report by Research and Markets, the global cable connectors market is projected to reach over $89 billion by 2025, driven by the increasing demand for efficient connectivity solutions in several industries.

The importance of cable connectors extends beyond simple connectivity; they play a crucial role in ensuring signal integrity, minimizing transmission losses, and enabling seamless data transfer. Effective cable connectors must be designed to withstand environmental factors, such as temperature fluctuations and exposure to moisture, which can significantly affect performance. A study from MarketsandMarkets highlights that the growth of smart devices and the Internet of Things (IoT) is further propelling the need for high-quality cable connectors, thereby transforming how devices communicate and interact in a networked environment.

As technology continues to evolve, so do the specifications and types of cable connectors available, ranging from standard options like USB and HDMI to specialized connectors for high-frequency applications. The right choice of cable connector can significantly impact the overall performance and reliability of an electronic system, making it imperative for manufacturers and users alike to understand their options and requirements thoroughly.

Common Types of Cable Connectors and Their Applications

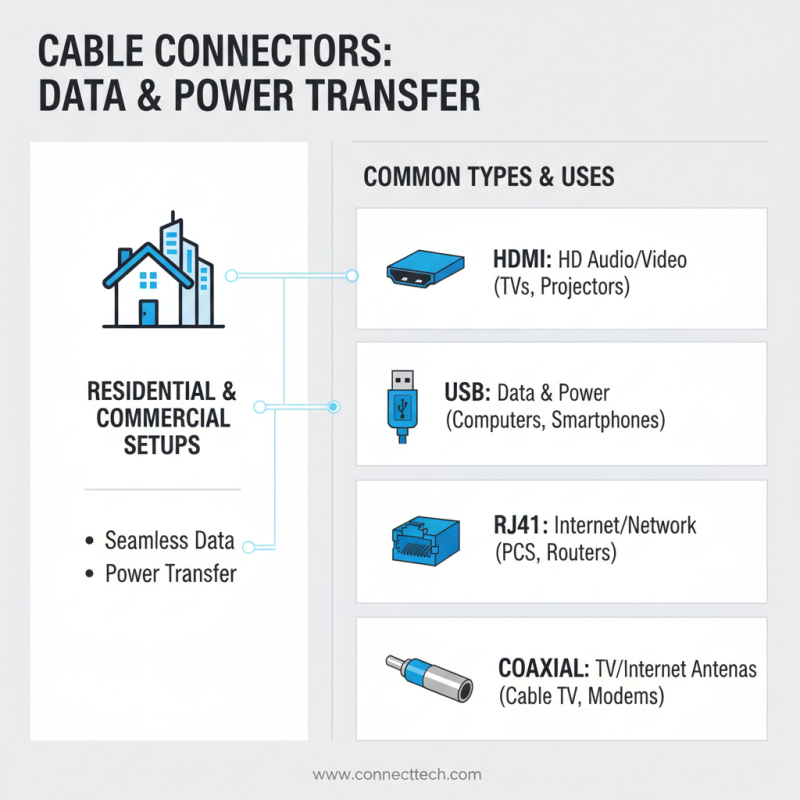

Cable connectors are integral components in both residential and commercial setups, facilitating the seamless transfer of data and power. Common types of cable connectors include HDMI, USB, RJ45, and coaxial connectors, each serving distinct purposes and applications. HDMI connectors are predominantly used for connecting high-definition devices like televisions and projectors, allowing for high-quality audio and video transmission. Meanwhile, USB connectors are versatile and widely used for connecting various devices, from computers to smartphones, providing both data transfer and power supply capabilities.

When it comes to networking, RJ45 connectors are a staple for Ethernet cables, enabling internet connectivity in homes and offices. Coaxial connectors, on the other hand, are commonly found in cable television and satellite installations, providing a reliable signal transmission for audio and video. Understanding these various connectors and their specific functions can significantly enhance one’s ability to set up effective and efficient connections.

**Tips:** When selecting cable connectors, always consider the compatibility with your devices and the anticipated data transfer speed. Furthermore, ensure that you choose quality connectors to minimize signal loss, especially for longer cable runs. Proper installation is crucial; follow guidelines closely to secure connections and avoid potential technical issues.

Step-by-Step Guide to Installing Cable Connectors

Installing cable connectors can seem daunting, but with a step-by-step approach, it becomes manageable. Start by gathering all necessary tools, including wire strippers, crimping tools, and electrical tape. Ensure that you have the correct type of cable connector for your specific application. Clean and prepare the cable ends, stripping them to expose enough wire for a secure connection.

Next, insert the stripped wire into the connector and use the crimping tool to fasten it in place firmly. Make sure that no strands are exposed outside the connector, as this can cause short circuits. After crimping, tug on the wire gently to ensure a strong connection. Finally, wrap the connection with electrical tape for an added layer of insulation and protection against moisture or environmental damage.

**Tips:** Always double-check your connections before powering on any devices. Using the right type of connector for your specific cables will greatly enhance performance and reduce the risk of failure. Lastly, practice good safety measures; turn off any electrical supply before you begin working to avoid the risk of shock.

Troubleshooting Tips for Common Connector Issues

When working with cable connectors, users may encounter a variety of common issues that can disrupt connectivity and performance. One frequent problem is poor signal quality, which can result from loose connections or corrosion on the terminals. To troubleshoot this, inspect the connectors for any visible dirt or oxidation, and ensure they are securely attached. Tightening the connection may resolve the issue, but if corrosion is present, cleaning or replacing the connector may be necessary to restore optimal function.

Another common issue involves intermittent connections, which can occur due to damaged cables or connectors. To address this, carefully examine the entire length of the cable for any signs of wear or cuts. Testing the cable with a multimeter can help identify the precise location of the fault. If the cable is damaged beyond repair, it should be replaced. Additionally, ensuring that connectors are compatible with the cables they are used with will prevent further issues and provide a reliable connection. Regular maintenance and inspection can help mitigate these problems and prolong the lifespan of cable connections.

What Are Cable Connectors? Types, Uses, and Installation Guide Explained - Troubleshooting Tips for Common Connector Issues

| Connector Type | Usage/Application | Installation Tips | Common Issues |

|---|---|---|---|

| RJ45 | Ethernet networking | Ensure proper wiring order (T568A or T568B). | Intermittent connection, slow speeds. |

| USB | Data transfer and charging | Check for dirt in the port before connecting. | Device not recognized, slow charging. |

| HDMI | Video and audio output | Secure the connection and avoid twisting the cable. | No signal, pixelated image. |

| Coaxial | Cable television, internet | Use a coaxial crimping tool for secure connections. | Signal loss, disconnected cable. |

| Molex | Power supply connections in computers | Align the connector properly before pushing in. | Overheating, device not powering on. |

Safety Considerations When Working with Cable Connectors

When working with cable connectors, safety should always be your top priority. These connectors, while essential for establishing secure electrical connections, can pose risks if not handled properly. Always ensure that the power is turned off before attempting to work on any connections to avoid electric shock. Wearing appropriate personal protective equipment, such as gloves and safety glasses, will also help safeguard against potential injuries from wire splinters or accidental contact with live wires.

Tips: Before starting any installation or maintenance work involving cable connectors, inspect your tools and connectors for any signs of wear or damage. Using damaged tools can compromise your safety and the reliability of the connections. Furthermore, familiarize yourself with the specific type of cable connectors you are working with, as each may have unique characteristics and requirements.

It's crucial to ensure that cable connectors are compatible with the cables being used. Using mismatched connectors can lead to overheating or even create fire hazards. When connecting cables, always adhere to the manufacturer's guidelines and local electrical codes. Proper torque specifications, for instance, should be followed to ensure secure and reliable connections. This diligence not only protects your immediate work environment but also enhances overall system performance.

Related Posts

-

How to Choose the Right Patch Panels for Your Network Setup

-

Exploring HDMI Switcher Innovations at the 138th Canton Fair in 2025

-

Ultimate Guide to Choosing the Best BNC Cables for Your Home Network

-

10 Essential Tips for Choosing the Right HDMI Adapters for Your Devices

-

The Ultimate Guide to Choosing the Right Patch Cord Cable for Your Network Needs

-

Exploring the Future of Coax Cable Innovations at China’s 138th Import and Export Fair 2025