2026 Top Trends in RF Connectors for Future Connectivity Solutions?

As technology rapidly advances, the demand for reliable RF connectors grows. These connectors play a crucial role in enabling seamless connectivity across various applications. In 2026, the landscape of RF connectors is set to evolve dramatically. Emerging trends will shape the future of connectivity solutions, influencing design, performance, and application areas.

One trend is miniaturization. Smaller RF connectors promise improved integration in compact devices. However, it also raises challenges in manufacturing and reliability. Additionally, the shift towards higher frequency operations is noteworthy. RF connectors must now support frequencies that were once considered extreme. This transition requires innovative materials and designs, posing a dilemma for engineers and manufacturers alike.

Sustainability will be another focus area. As industries push for eco-friendly solutions, RF connectors must adapt to meet these new standards. Material choices and recycling processes are vital. They directly impact environmental footprints while ensuring connectivity. With these trends, the future of RF connectors holds great promise but also demands careful consideration and innovation.

Key Innovations in RF Connector Design for Enhanced Performance

The design of RF connectors is evolving rapidly to meet the demands of advanced connectivity solutions. The market is projected to grow significantly, with a report estimating a compound annual growth rate (CAGR) of 8.9% from 2021 to 2027. This growth drives innovation, focusing on enhancing performance metrics like frequency range and durability.

Key trends in RF connector design prioritize miniaturization. Smaller connectors allow for more compact devices, crucial for applications in IoT and 5G technologies. New materials are being used to improve resistance to environmental factors, like humidity and temperature fluctuation. However, this drive for miniaturization raises concerns about the ability to maintain signal integrity. Developing solutions to address these challenges is essential.

A significant insight from the industry shows that nearly 30% of reported connector failures are due to poor design and environmental exposure. This statistic underscores the need for robust testing protocols and innovative designs. Engineers are exploring advanced simulation techniques to predict performance under various conditions. These approaches can help mitigate risks but require continuous investment and adaptation. There's much room for improvement in achieving long-lasting, high-performance RF connectors.

2026 Top Trends in RF Connectors for Future Connectivity Solutions

| Trend | Description | Expected Impact | Key Innovations |

|---|---|---|---|

| Miniaturization | Designing smaller connectors for compact devices. | Increased integration in portable devices. | High-density interconnect technology. |

| Improved Data Rates | Connectors designed for higher speeds and lower latency. | Enhanced performance in data-heavy applications. | Advanced material usage for signal integrity. |

| Environmental Resilience | Connectors designed to withstand harsh environments. | Increased reliability in outdoor and industrial applications. | Weatherproof and ruggedized designs. |

| Smart Connectors | Integration of sensors and smart technology into connectors. | Enhanced functionality and diagnostics. | IoT-enabled connectivity solutions. |

| Sustainability | Use of eco-friendly materials and processes in production. | Better environmental compliance and public perception. | Recyclable and biodegradable components. |

Emerging Materials in RF Connectors for Future Applications

Emerging materials are reshaping the landscape of RF connectors. Designers are exploring advanced composites that offer better thermal and electrical performance. These materials promise lower insertion loss, which boosts signal quality. Lightweight options also contribute to overall efficiency. Innovative polymers show promise in high-frequency applications. They are flexible yet durable, challenging traditional metals.

However, the shift to new materials poses challenges. Some may not withstand environmental stresses as well as metals. Reliability in diverse conditions must be thoroughly tested. Manufacturers need to ensure that these alternatives can handle extreme temperatures and humidity. Real-world applications have shown mixed results. As we embrace innovation, careful evaluation remains crucial.

Sustainability is becoming a focus area too. Biodegradable materials could reduce waste in electronic components. There’s potential, but the technology is still evolving. Balancing performance with eco-friendliness is a rich area for research. Understanding the limitations of new materials is essential. This constant quest for improvement drives the industry forward. The future of RF connectors is promising, but caution is necessary.

Trends in Miniaturization and Integration of RF Connectors

The trend of miniaturization in RF connectors is accelerating. Smaller devices are everywhere, from smartphones to IoT applications. This demands connectors that fit into tighter spaces without compromising performance. The challenge lies in maintaining signal integrity while reducing size. Many designs struggle to balance these aspects. Engineers must adapt constantly.

Integration is also key. Combining multiple functions into a single connector can save space. This trend is particularly evident in automotive and communication sectors. However, integration can lead to heat management issues. As more components are crammed into one package, cooling becomes paramount. This remains an area needing further exploration.

As miniaturization and integration advance, they create potential pitfalls. Designers face the risk of over-engineering. Complicated designs can lead to increased costs and potential failures. Simplifying the design while maintaining performance is a difficult task. Addressing these challenges is crucial for the overall success of RF connector innovations in the future.

Impact of 5G and IoT on RF Connector Development

The rise of 5G and IoT technologies is shaping the future of RF connectors. These advancements demand higher frequencies and better performance. A recent report indicates that the global RF connector market will reach $4.3 billion by 2026, driven largely by 5G infrastructure. As more devices connect, the need for reliable and efficient RF connectors grows.

IoT devices are proliferating. In 2023 alone, billions of devices are expected to connect to networks. This trend is pushing manufacturers to innovate. They are focusing on miniaturization and enhanced performance. Traditional connectors may not meet the needs of next-generation applications. This presents a challenge for designers. They must consider durability and flexibility in their solutions.

Tips: Focus on connector compatibility in your designs. This will prevent costly revisions down the line. Keep an eye on emerging standards for better integration. As technologies evolve, ensure your connectors can adapt to new requirements. Continuous learning is crucial. Stay informed about market trends to guide your development strategies.

2026 Trends in RF Connectors Driven by 5G and IoT

This chart illustrates the top trends in RF connectors for 2026, emphasizing the impact of 5G and IoT on connector development. The importance levels reflect industry priorities, noting the significant integration of IoT and the need for high-frequency performance.

Sustainability and Environmental Considerations in RF Connector Production

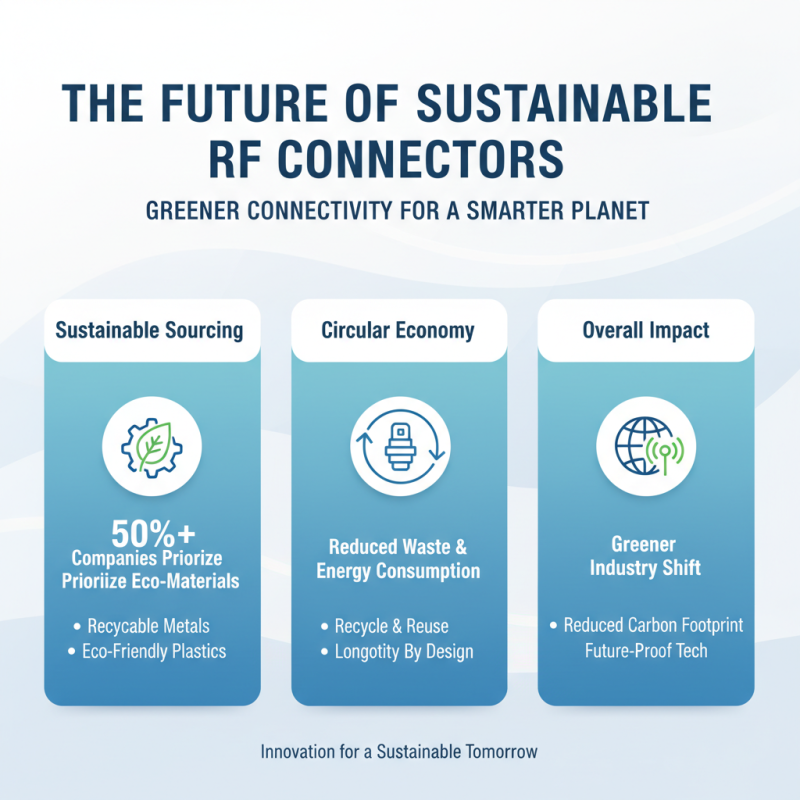

The future of RF connectors involves a strong focus on sustainability. As industries shift towards greener practices, RF connector production must evolve. Reports indicate that over 50% of companies now prioritize sustainable sourcing of materials. This includes the use of recyclable metals and eco-friendly plastics. Adopting circular economy principles can significantly reduce waste and energy consumption during production.

Manufacturers face challenges in balancing performance and environmental concerns. Traditional materials may offer better conductivity but often harm the planet. A study found that implementing sustainable practices can reduce carbon footprints by up to 30%. The push for eco-conscious designs is evident. Yet, the industry grapples with higher costs for greener alternatives. Finding this balance is critical.

Innovative approaches are emerging. Some companies are exploring bioplastics as viable substitutes. Others turn to energy-efficient manufacturing processes. However, they must tackle quality concerns alongside these advancements. Industry feedback reveals a need for further research. Stakeholders are keen on improvements but hesitate over potential compromises in performance.

Related Posts

-

What is RF Connectors and How Do They Work?

-

2025 Top RF Connectors Guide for Best Performance and Compatibility

-

Exploring HDMI Switcher Innovations at the 138th Canton Fair in 2025

-

What is Telephone Cable and How Does it Work in Modern Communication

-

How to Choose the Right Patch Panels for Your Network Setup

-

10 Essential Tips for Choosing the Right Bulk Cable for Your Projects?